Maintaining quality edge major focus of axe maker

Stick NZ

Stick NZ

Category:

Location:

Category:

Location:

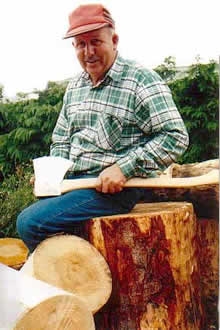

[caption id="attachment_1710" align="aligncenter" width="220"] Tuatahi Racing Axes & Saws

founder Eddie Fawcett with one of the Masterton company's world-beating products[/caption]Whether to

outsource or insource, that is (one of) the questions.

Tuatahi Racing Axes & Saws

founder Eddie Fawcett with one of the Masterton company's world-beating products[/caption]Whether to

outsource or insource, that is (one of) the questions.

For axe and saw maker Tuatahi Racing Axes & Saws, the question resolved itself a number of years ago says its office manager, Jo Fawcett.

The 45 year old company, started in Masterton by her father Eddie who as a competitive axeman was originally asked by others to sharpen their blades, and then to make the finished product, used to get others to carry out the forging component of making the axe head.

“But we found that some of our axes were bending and breaking,” she says. The company made the decision to bring this forging side back and also bought the power-hammer required to form the axehead.

Tuatahi orders 25 tonnes of the specialty steel at a time in 3 – 5 metre lengths. A five kilo block of this is in turn crafted into an axehead.

There is still a large degree of hand forming in the axes and Eddie, as well as Jo’s brother Grant are still competitive axemen and “they have a feel how an axe or saw should run.”

“They’re very particular, and if they aren’t happy will keep tweaking the blade or edge until it is just right. It is a skill that takes years to develop. Grant is more into the management side of the company these days, but is teaching the other guys, passing the skills on.”

As well as the racing axes and saws, Tuatahi is also looking to expand its working implements side of the business. Racing axes and saws currently make up about 60% of the company’s almost $1 million a year turnover.

In this regard Jo Fawcett notes two particular trends.

The USA’s Obama administration has opened up more heritage trail areas in America’s forested areas. The US Forest Service only allows hand held equipment to be used in clearing and maintaining these trails, and Tuatahi’s M-tooth and Peg and Raker Work saws are the preferred implement for these gangs.

The greenie movement and a bit of a back to basics wish among some foresters and farmers is also seeing the revitalisation of interest in using hand axes and saws instead of chainsaws.

“A lot of silverculturists are using hand saws,” says Fawcett. “They like to know they’ve done a day’s work, and there’s the whole fitness aspect for some people too.”

From a business point of view, Tuatahi is looking to become more streamlined.

“At the beginning of the year, we decided we wanted to start at the beginning,” she says, “and really look at how we are doing things.”

This started with how Tuatahi takes orders, organises the factory, invoices and packages its products. “We’ve concentrated on having more systems in place.”

This should help reduce the axes and saw waiting times (for orders) and enable Tuatahi to have actual stock implements on its shelves.

“That would allow us to go down a completely different path, instead of chasing our tail all the time,” Fawcett says.

“Making sure we’re on top of our game would enable us to look more fully into that United States market, where we know we have a big demand for what we produce.”

She says the USA doesn’t have any axe manufacturer which produces the same quality as Tuatahi, the nearest competitor being hatchet makers, “which is not the same market as us.”

One new market would be firefighters’ axes, which the company hasn’t yet had the time to investigate properly.

Automation of some of its processes, particularly to produce the $295 work axes is something that Tuatahi would like to develop. Having had a limited success with a prototype machine to help grind the teeth of its racing saws means that the company knows it has a challenge to replicate some of the handmade operations.

“We’re keen on R&D,” she says, “we have to reinvent ourselves all the time. We encourage the staff to look at ways to streamline production, and if there’s ways to speed things up, that will be great as a way for us to catch up on our orders.”